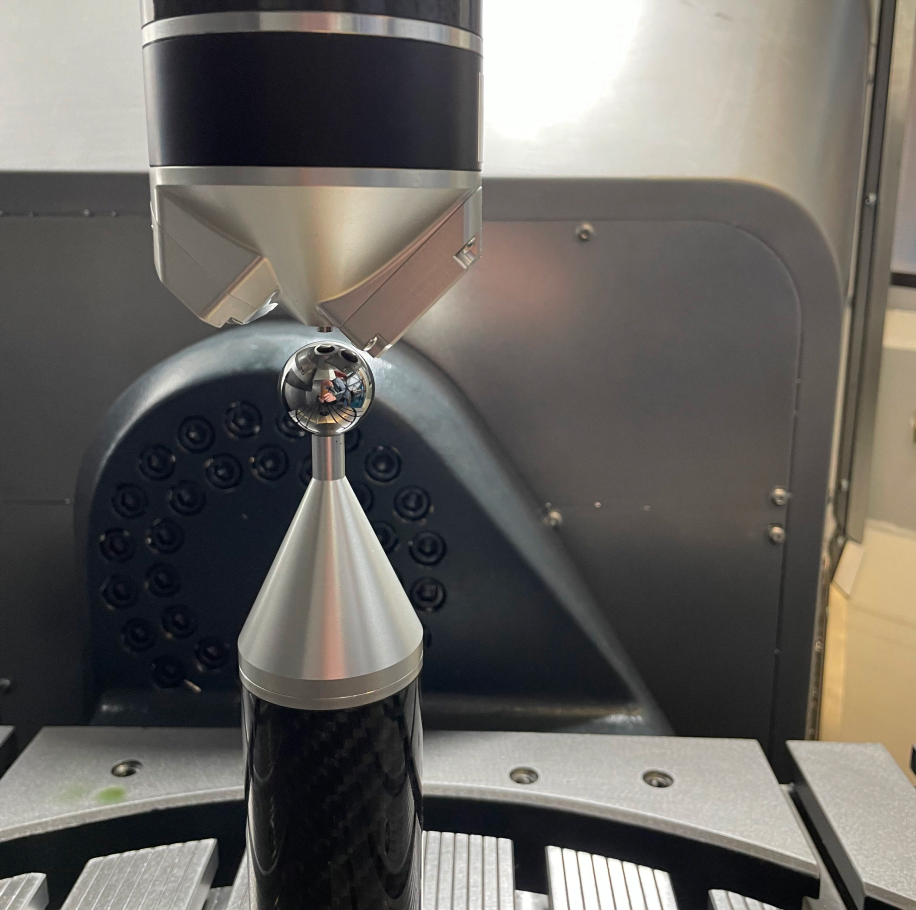

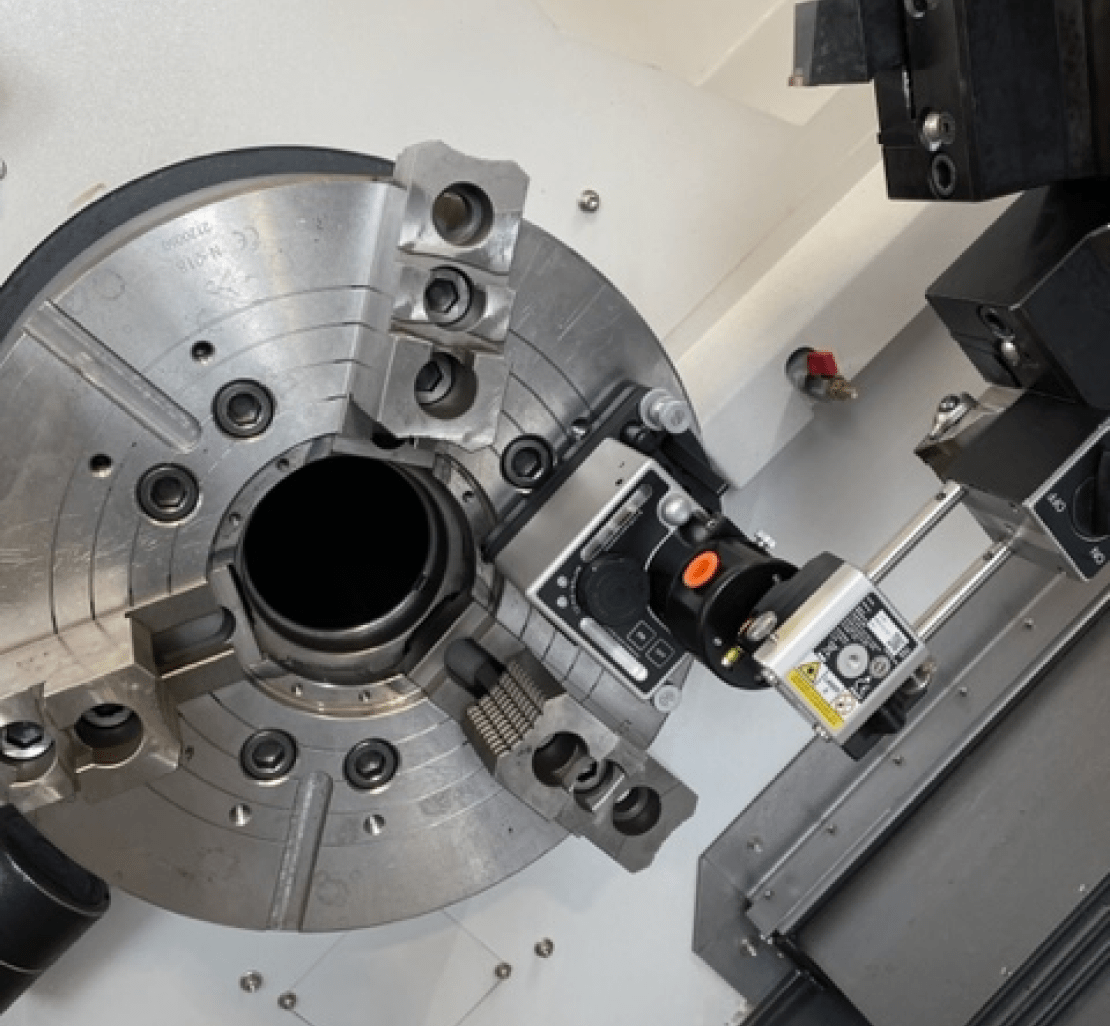

Our equipment is ready at all times and we do not need to make preliminary checks at your factory. That is why we are able to carry out calibration shortly after your request. We can then immediately adjust the machine or recommend further steps.

Precision with passion

From diagnostics to adjustments, advice and equipment sales. We are your guide to increasingly precise engineering.

Reliable solutions for CNC machines

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(280.9208%2082.81242%20-98.48666%20334.09179%20122.4%20298.4)%22%2F%3E%3Cellipse%20fill%3D%22%23dfdfdf%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(233.07018%20-206.40166%20152.52753%20172.23514%20457.3%20834.2)%22%2F%3E%3Cellipse%20fill%3D%22%23f1f1f1%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(192.1837%2094.9831%20-125.62625%20254.1854%20887.4%20138.2)%22%2F%3E%3Cellipse%20fill%3D%22%230b0b0b%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(17.9%20-494.2%2083.6)%20scale(353.88161%20181.93572)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

%22%20transform%3D%22translate(1.7%201.7)%20scale(3.47656)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23bebebe%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-53.8%20219.7%20-176)%20scale(134.15924%2055.21701)%22%2F%3E%3Cellipse%20fill%3D%22%23131313%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-55.79891%2039.86886%20-65.98855%20-92.35502%2052%20214.8)%22%2F%3E%3Cellipse%20fill%3D%22%23060606%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(26.09194%2016.75073%20-23.75841%2037.00753%20238.8%20239.3)%22%2F%3E%3Cellipse%20fill%3D%22%23292929%22%20cx%3D%2294%22%20cy%3D%225%22%20rx%3D%22113%22%20ry%3D%2259%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

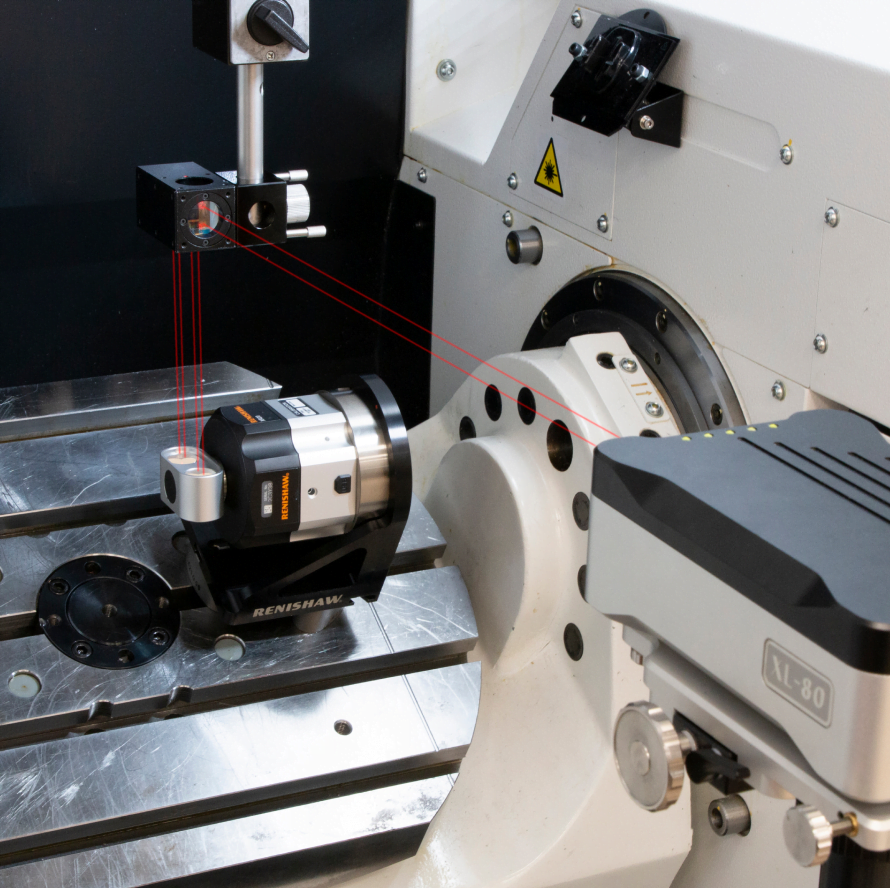

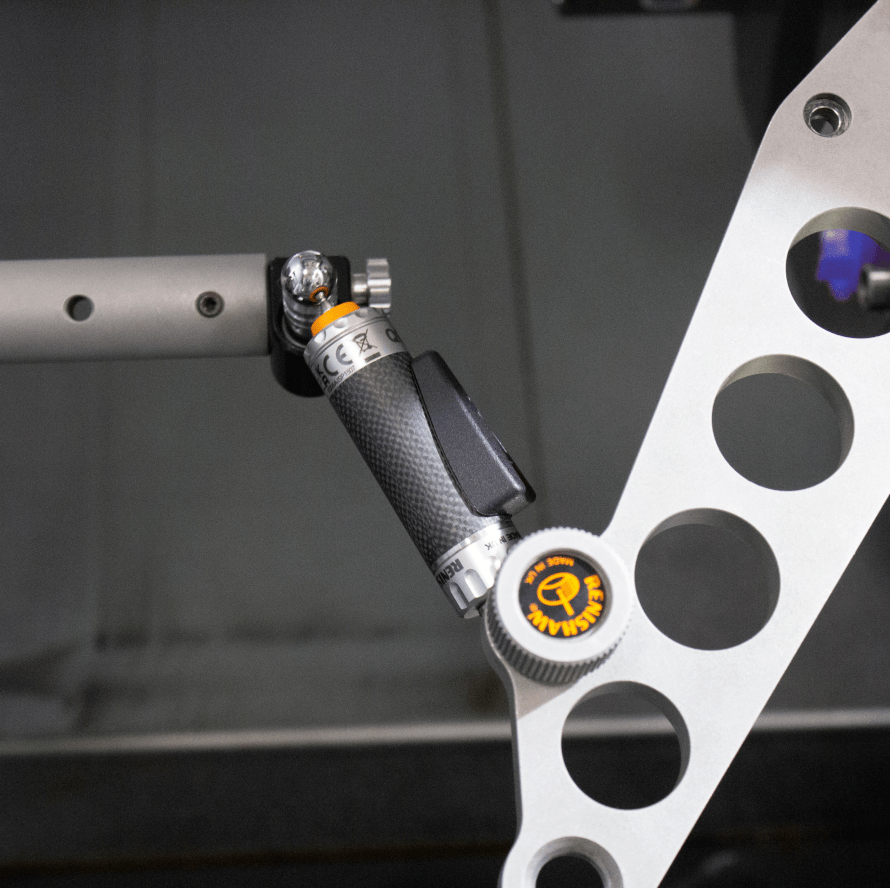

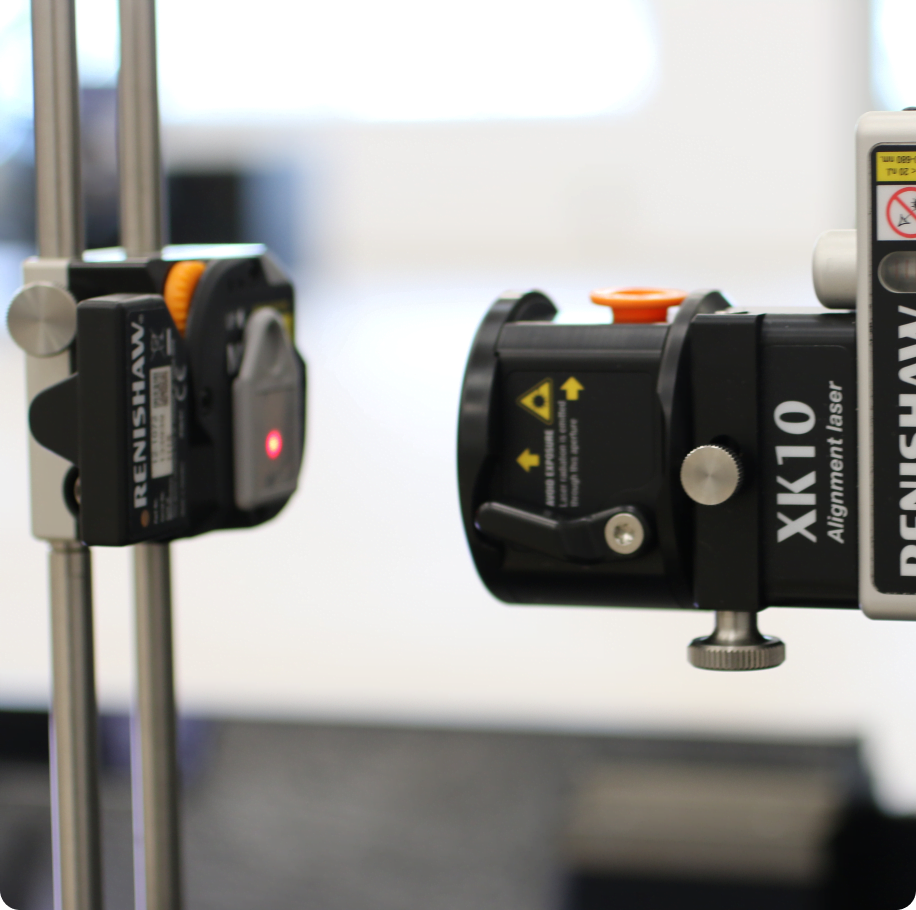

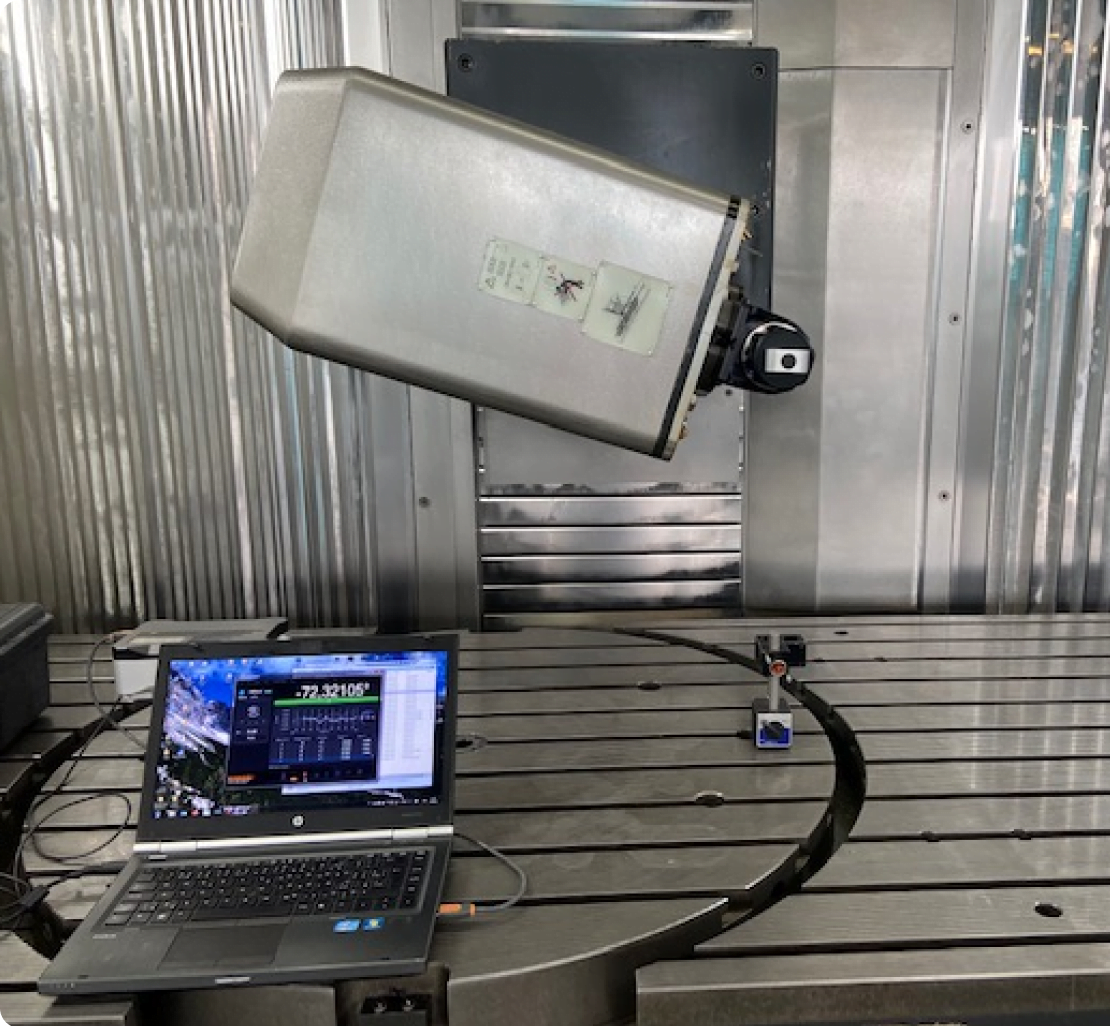

Equipment sales

and trainingWhat we do, we train as well. You may find yourself in a situation where it makes more sense to take care of your machines internally. Even then, you have our full support. We will advise you on the equipment needed and teach you how to use it.

- mission

- values

- mission

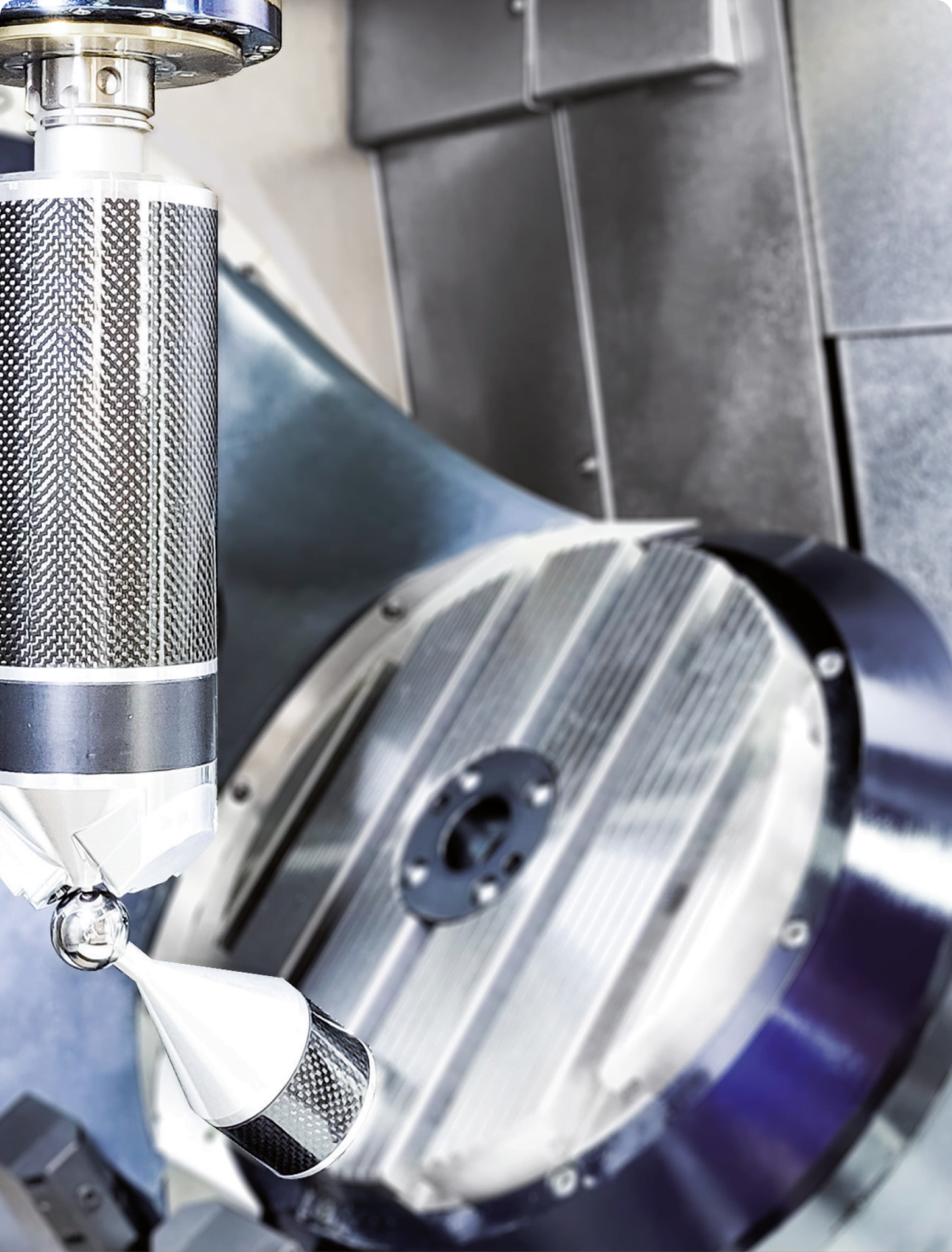

To ensure excellent performance and precision throughout the lifespan of your machines

We swiftly provide calibrations, software adjustments and accuracy trend monitoring to all CNC machine owners and suppliers to minimise unplanned downtime and maintenance costs.

%22%20transform%3D%22translate(1.8%201.8)%20scale(3.57813)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(120.41143%204.74595%20-2.65855%2067.45105%20146%2010)%22%2F%3E%3Cellipse%20fill%3D%22%23121212%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-77.19484%208.23985%20-4.05896%20-38.02628%20213%20123.7)%22%2F%3E%3Cellipse%20fill%3D%22%23323232%22%20cx%3D%2267%22%20cy%3D%22237%22%20rx%3D%22255%22%20ry%3D%2228%22%2F%3E%3Cellipse%20fill%3D%22%23f5f5f5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-26.77638%20-5.8382%2028.8097%20-132.13322%20111%2073)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

- values

What we

agree on, standsWe approach our contracts with diligence because we understand the importance of having perfectly working machines. We act openly in an effort to find the optimal solution.

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%23fdfcfe%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(178.64633%20-64.51089%2050.12612%20138.81142%20626.2%2045.2)%22%2F%3E%3Cpath%20fill%3D%22%23262527%22%20fill-opacity%3D%22.5%22%20d%3D%22M-55.5%20277.3L77%20964.3l747.9-411.5z%22%2F%3E%3Cellipse%20fill%3D%22%239e9f96%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-65.49255%20-124.21768%20352.24052%20-185.71536%20741%20835.8)%22%2F%3E%3Cellipse%20fill%3D%22%23e7e6e8%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(43.4%20-67.3%2063.4)%20scale(79.41134%20118.19453)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Where we helped before

kaleb TEC s. r. o.

Jsme česká značka. Staráme se o CNC stroje po celé Evropě. Svědomitě. Férově. Se zápalem.