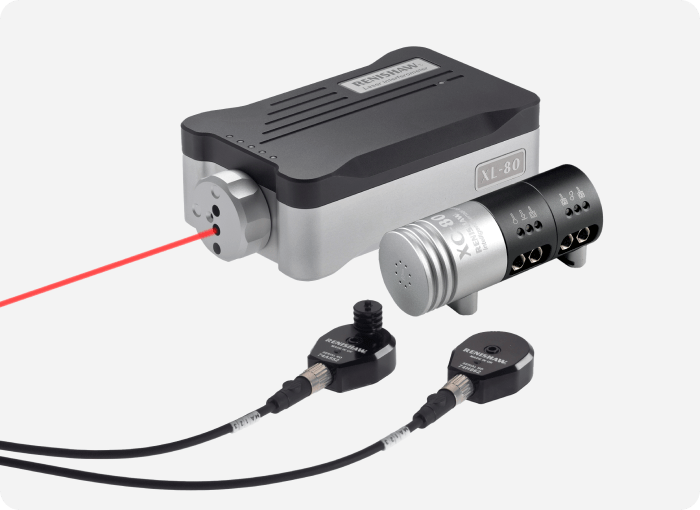

The world benchmark for precision and flexibility in the calibration of machine tools, CMMs and special instruments. Subtle dimensions also allow for clamping it directly into the machine and is has the function of strengthening the laser beam measurement up to 80m.

Precision care equipment

In addition to specialised care, we also provide precise lasers and state-of-the-art measuring equipment.

Equipment

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%236c6c6c%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(21.5037%20-126.88219%20172.40224%2029.21833%20381.3%20165)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-94.9%20106%2045.2)%20scale(306.41804%2099.15634)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-58.24418%20598.48502%20-110.37141%20-10.74128%20698.6%20262)%22%2F%3E%3Cellipse%20fill%3D%22%23676767%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-10%201004.5%20-2041.7)%20scale(89.3383%2054.39037)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

XL-80 laser

interferometer%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%23979797%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-154.78641%20-221.9024%2078.89145%20-55.03016%20257.3%20112.4)%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20d%3D%22M-42.4%2028.7l385.6%20475.8-385.6%2019.1z%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-315.46717%20-621.81977%20115.2166%20-58.45271%20644.3%20172.2)%22%2F%3E%3Cellipse%20fill%3D%22%23858585%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-68.91978%2012.94657%20-15.95502%20-84.93498%20212.5%2021.8)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

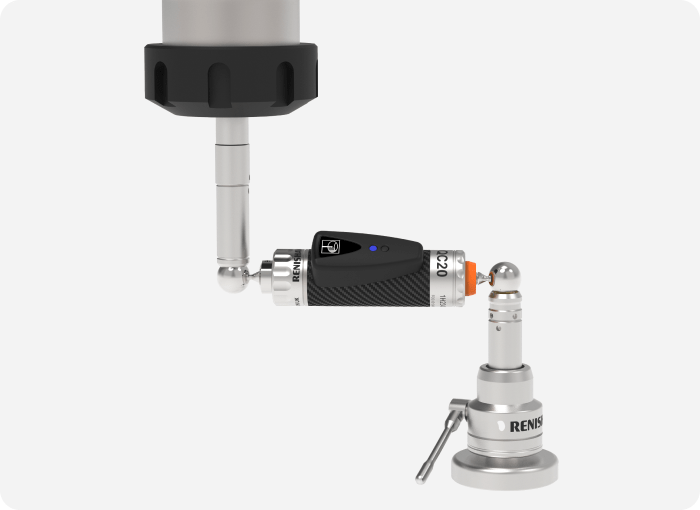

QC20-W ballbar

A device proven over the years for its very quick accuracy diagnostics of machines that allow circular interpolation. Fastening is with magnets, perhaps directly on the piece. The Trend function can be used with a great advantage for predictive maintenance planning.

%22%20transform%3D%22translate(1.4%201.4)%20scale(2.73438)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23555%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-169%2068.4%2048)%20scale(35.48939%2082.72914)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-42.89117%20-9.59005%2048.99235%20-219.11657%2015.3%20109.2)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%22227%22%20cy%3D%22109%22%20rx%3D%2244%22%20ry%3D%22255%22%2F%3E%3Cellipse%20fill%3D%22%23696969%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-22.55346%20-4.53016%209.91963%20-49.385%20126.5%20103.5)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

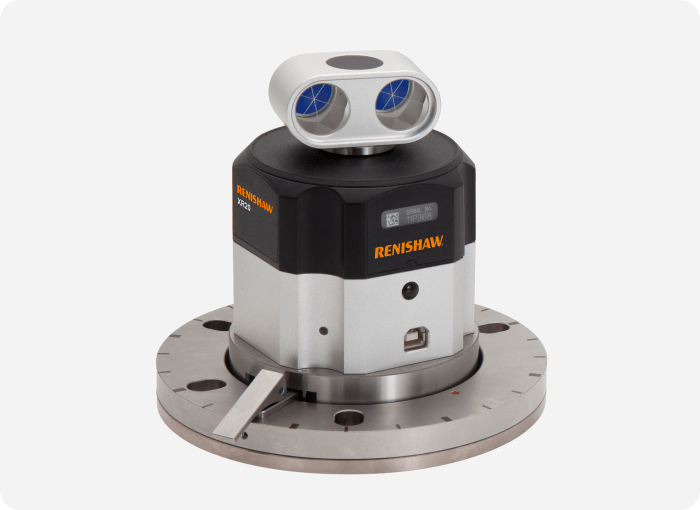

5X Analyzer

Ballbar for 5-axis machines. Comprehensive diagnostic tool for static and dynamic accuracy evaluation with the inbuild compensation engine. The analysis results are a static and dynamic accuracy deviations in the machine volume, including compensation tables.

%22%20transform%3D%22translate(1.4%201.4)%20scale(2.73438)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%232d2d2d%22%20cx%3D%2217%22%20cy%3D%22127%22%20rx%3D%22130%22%20ry%3D%2272%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(56.58452%20-23.8244%2098.9522%20235.018%20219.8%2071.7)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(.9%20-770%2010991)%20scale(103.25796%2043.19016)%22%2F%3E%3Cellipse%20fill%3D%22%237e7e7e%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(5.7%20-864.7%201546.6)%20scale(36.83707%2054.05625)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

XK10 alignment

laserExtremely flexible tool for measuring and adjustment geometries up to 30m. Above all, the ability to measure and, in Live mode, adjust both horizontal and vertical straightness at the same time is unique. It is wireless and does not mind beam interruptions.

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%23727272%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-108.3491%203.08082%20-15.49998%20-545.1181%20326.9%2042.4)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(96%20203.9%20443.7)%20scale(384.23912%20167.2313)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(31.07506%20334.97901%20-122.92794%2011.40368%2051.9%20329.9)%22%2F%3E%3Cellipse%20fill%3D%22%237a7a7a%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(15.23465%2067.96971%20-176.45181%2039.5497%20337.8%208.4)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Touch set

Patented tool for calibrating the diameter and length of workpiece set-up and inspection probe. The spring-loaded mandrel with lock eliminates the influence of operator and ensures repeatability of length calibration. A built-in calibration ring adds diameter calibration.

%22%20transform%3D%22translate(1.4%201.4)%20scale(2.73438)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23545454%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-6.54017%2070.04662%20-49.93194%20-4.66208%20124.6%2093.4)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-16.27573%20-206.8027%2043.94825%20-3.4588%20230.2%2094.6)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(10.6%20-454.2%20117.8)%20scale(48.40082%20156.65213)%22%2F%3E%3Cellipse%20fill%3D%22%23585858%22%20cx%3D%22124%22%20cy%3D%2277%22%20rx%3D%2232%22%20ry%3D%2237%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

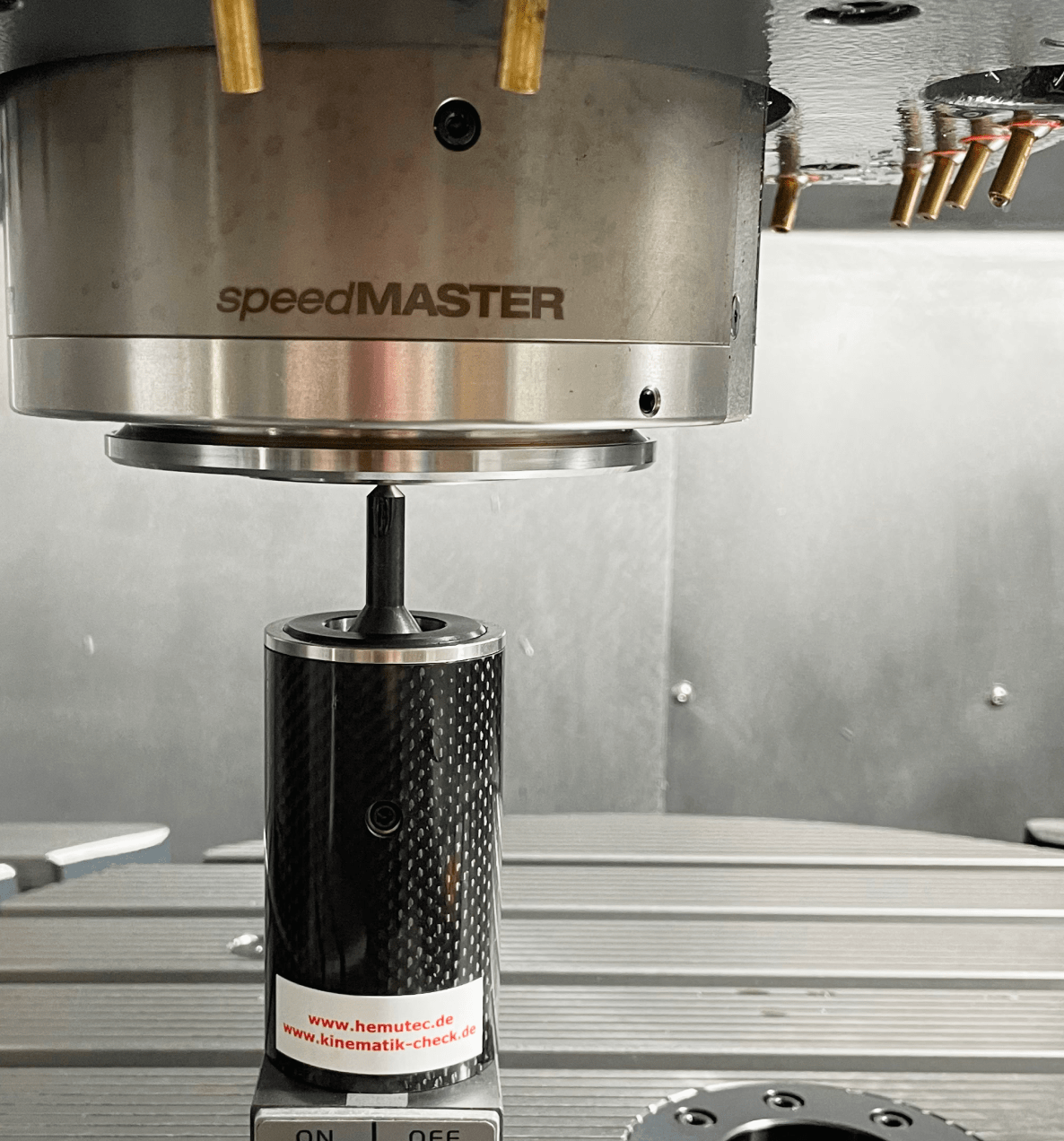

XR20-W rotary axis calibrator

Small but clever. Wireless with Bluetooth connection. A separate clamping ring with bayonet attachment greatly simplified the installation of the device on the machine. Measure and compensate rotary tables and tilting axes at customer selectable steps.

We train our customers in data capture, analysis and machine adjustments according to the deviations measured.

Practical informationAll our training is practically oriented. Most of the training takes place directly at the machine. That is why we limit the number of participants to three, so that everyone can get enough practice.

It is recommended to consult the appropriate workwear according to the training location.

Principles of equipment operation including safety and maintenance

Installation of the measuring equipment at the machine and setting up the measurement software for data capture

How to distinguish between operator and machine errors, including examples

Measuring program creation for calibrated machine

Data capture at the machine. Data evaluation according to the international standards and what data tells us about machine deviations

Machine fix according to the measured data, MP parameters, compensation tables

Where we helped before

kaleb TEC s. r. o.

Jsme česká značka. Staráme se o CNC stroje po celé Evropě. Svědomitě. Férově. Se zápalem.