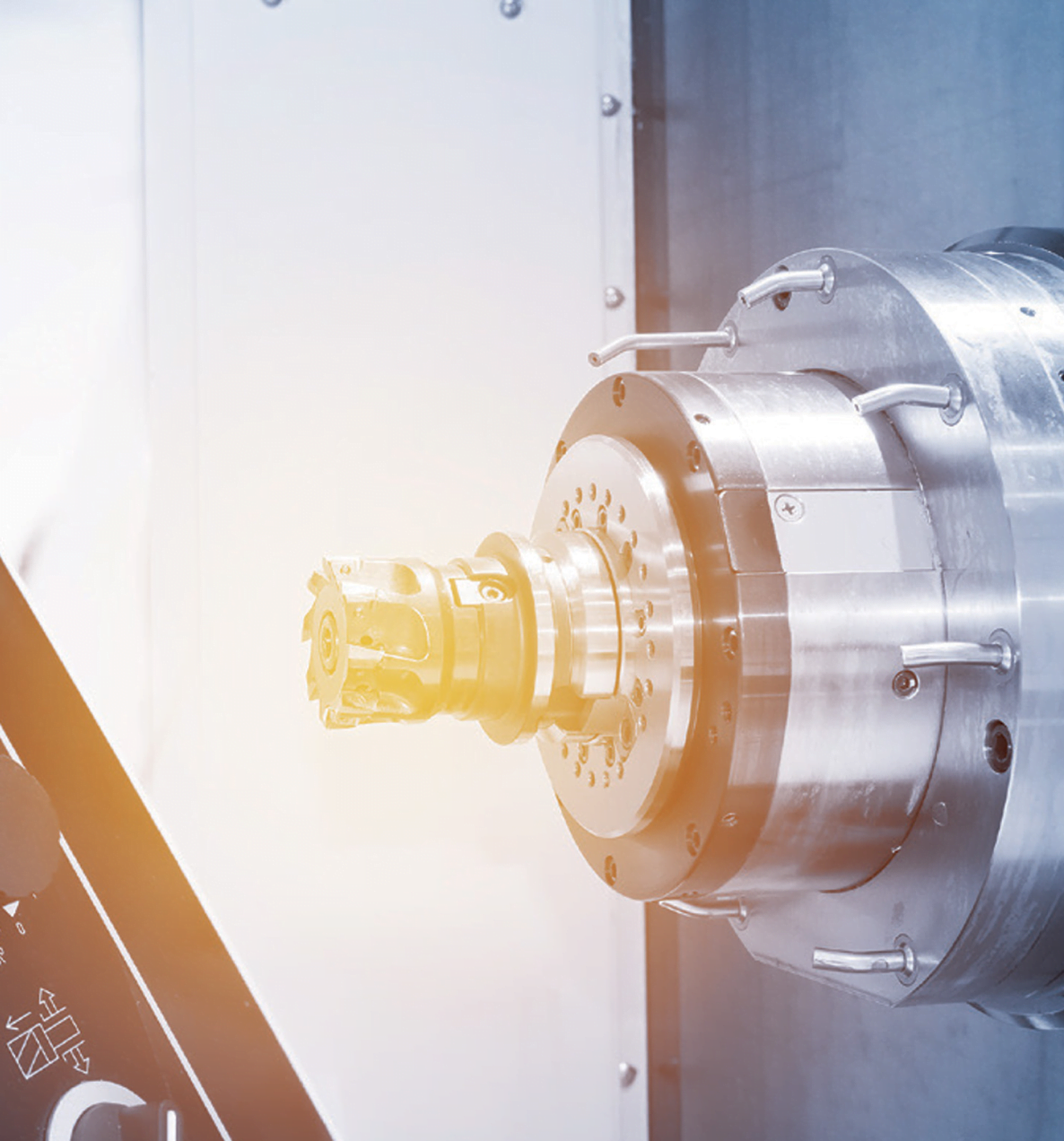

We will measure the deviation the machine operates with and identify the cause.

If no parts need to be replaced, we will adjust the machine parameters to bring the accuracy back within the required tolerance. Or even better.

We will make sure your CNC machine can handle your next project. Get in touch. We respond quickly.

We will measure the deviation the machine operates with and identify the cause.

If no parts need to be replaced, we will adjust the machine parameters to bring the accuracy back within the required tolerance. Or even better.

For years we have been establishing excellent relationships with machine tool manufacturers, suppliers and service companies. Thanks to that, we can help you arrange the necessary interventions before calibration in the case of a mechanical malfunction.

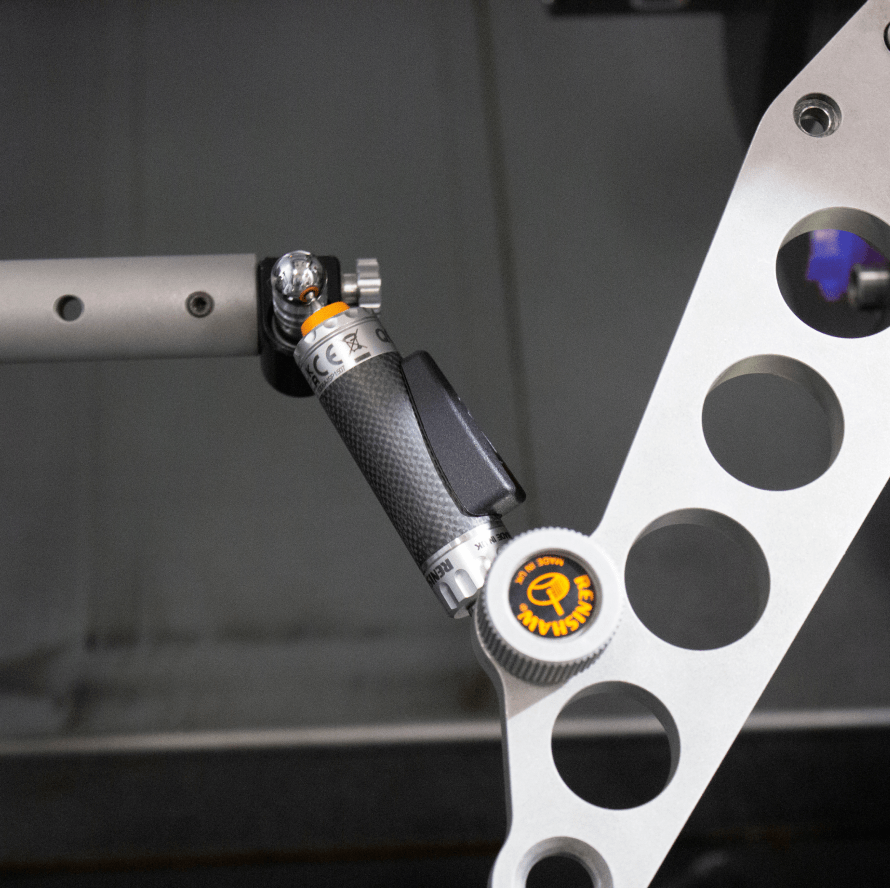

If you want to take care of your machines in-house, we will teach you how to operate the needed measuring equipment and work with the data obtained.

We also sell the instruments we work with on a daily basis.

Determining reasons, why the accuracy trend in production is attacking the tolerance limits

Metrology assistance during long machine beds alignment and geometry adjustments

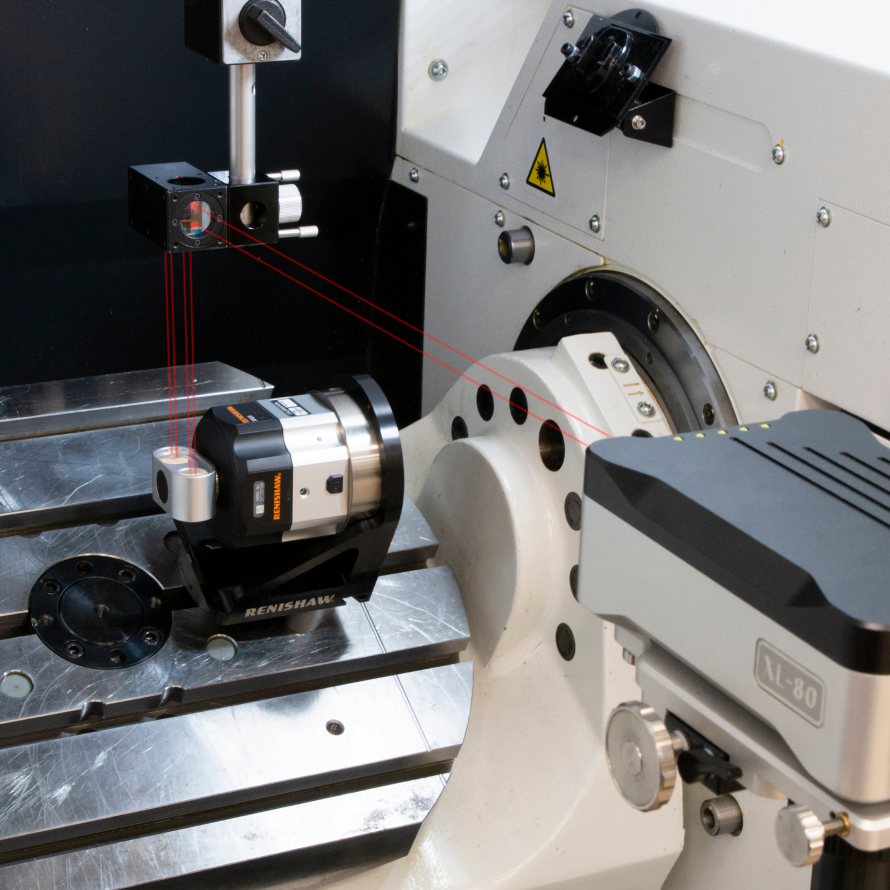

Laser pitch error calibration and error mapping after relocation or a change of measurement scale

Regular verification of CNC machine accuracy and wear trends

Independent verification of the condition of a used or new machine

Jsme česká značka. Staráme se o CNC stroje po celé Evropě. Svědomitě. Férově. Se zápalem.